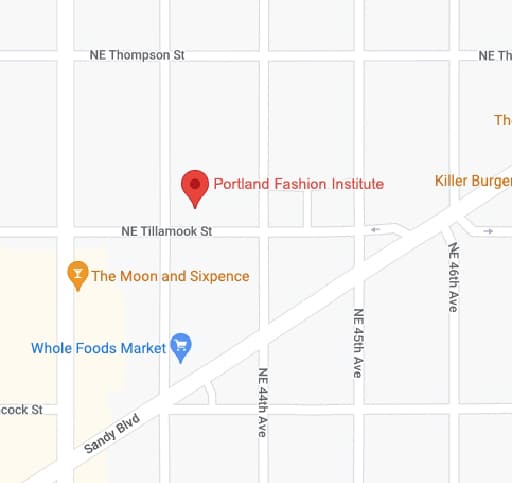

Clark County Teen Wins $20,000 Portland Fashion Institute Scholarship

Aidan Clause’s transformational designs draw inspiration from Brutalist aesthetics By Andrew Jankowski Willamette Week A high-school senior from Clark County, Wash., won the top prize