Sustainability was in focus at M.A.G.I.C. Las Vegas, August 2019. Photo: PFI

Executives from Lenzing and Saitex talk sustainability in fabrics (courtesy of Fashion Frameworks)

Sustainability in fashion has become increasingly important. And one way for a brand to become more sustainable is through its fabric. We talked to two market leaders, Saitex and Lenzing, about fabric sustainability.

Saitex. Founded by Sanjeev Bahl, Saitex is a sustainable factory specializing in denim manufacturing. Top clients include Everlane, Edwin, J. Crew, and Madewell, among others. Saitex’s impressive factory is based in Vietnam and they’re opening a second production facility in Los Angeles. Here, we talk to Virgina Rollando, Saitex’s sustainability project manager.

What makes a fabric sustainable?

Virgina Rollando: Sustainability is always difficult to define, particularly when speaking about fabrics. Organic cotton is the least harmful option for soil health, however it requires large amounts of water. Recycled polyester from waste reduces what goes to landfill, and the amount of energy required in production, however it releases microfibers in washing. What makes a fabric sustainable is not black and white definition.

Typically, sustainable fabrics are derived from eco-friendly resources, such as sustainably grown fiber crops or recycled materials. At Saitex, we have extended these requirements to include how fabrics are made. Saitex has recently achieved GOTS and GRS certifications for organic and recycled garments – this means that after we receive a certified fabric, we can ensure that the whole garment and chemicals used also have the highest standards.

At Saitex, we strive to make sure there is a clear understanding of the fabric’s complete process from seed to bolt. Not only do we collaborate with fabric suppliers, we are the partner of choice for our brands when testing and refining any innovations. We share a level of transparency with our brands, so fabric innovations do not remain exclusive for very long, we try to be as open source as possible. We want to see our impact spread. We are also under construction of an on-site mill at our Vietnam facility opening in 2020, which will produce the most sustainable fabrics available, using renewable energy, recycled wastewater, and Bluesign chemicals.

Photo: Jon Galbarriartu

In your opinion, what are three ways a fashion brand can become more sustainable?

Virginia Rollando: The lowest hanging fruit for a fashion brand is to incorporate sustainable fabrics into its products. This is just a conscious decision every company leader must make. The options available across all categories and price points are vast. There have been significant adjustments to the cost of making these responsible decisions. Similarly, there are increasing options for sustainable production at all scales, both international or domestic, that utilize renewable energy sources.

Fashion brands should take more responsibility over all steps and aspects of production. When speaking of social sustainability, we greatly support the Fairtrade program, which connects brands directly with employees on the factory floor that receive a premium for every Fairtrade purchase, and are empowered to vote collectively on what projects to invest in. In terms of environmental sustainability, too often a blind eye is turned towards fabric waste. Brands ignore the amounts of fabric offcuts and waste garments that are an inevitable aspect of production, and are often asked to be incinerated. SAITEX offers brands the option to upcycle them into new garments or products such as tiles and furniture.

Photo: Jon Galbarriartu

Lenzing. Lenzing has been producing fibers from wood for over 80 years. They make fibers under their four brands (Tencel, EcoVero, Veocel and Lenzing) for various industries like fashion, home textiles, outdoor, among others. Here, we talk to Lenzing’s Tricia Carey about sustainable fabrics.

What makes a fabric sustainable?

Tricia Carey: The definition of sustainability is rather blurry now. Each company is defining sustainability in their terms—some are addressing current standards and others are pushing to triumph beyond.

I view a sustainable fabric as having the least amount of total environmental impact based on current available technology. This encompasses raw material, spinning, weaving or knitting, dyeing and finishing, consumer use and after-life. Starting with preferred raw materials with the least impact on water usage, land, and chemicals. TENCEL™ lyocell is produced in a closed loop production process and is biodegradable and compostable. Our latest innovation is TENCEL™ Lyocell with REFIBRA™ technology which uses cotton scraps to make a new lyocell fiber.

Photo: Lenzing

In your opinion, what are three ways a brand can become more sustainable?

Tricia Carey:

1) Education. Brands need to learn about current standards and issues. They need to assess the impact of their current supply chain and product assortment, as well as review what leading brands are doing to have scalability. Environmental impact is a common thread across all companies.

2) Strategy. Next brands need to set a strategy with measurable goals in a timeframe. Typically, brands set a materials strategy based on cotton, synthetics and wood-based cellulosics.

3) Transparency. Work with transparent and reliable partners who share the same vision and goals. Visit these suppliers to see what they are doing and how their factories run. Lenzing often hosts tours of our facilities for customers and once they see how we transform trees into fiber, there is truly another level of understanding.

Fashion Frameworks: Can you expand on Lenzing’s sustainability program?

Tricia Carey: Overall, the entire fiber industry produces over 100 million tons of fibers every year. At Lenzing, we produce viscose (branded as LENZING™ ECOVERO™), modal and lyocell (branded as TENCEL™ Fibers). We believe in the concept of circular economy and closed-loop processes. We dedicate our innovative spirit and engineering excellence to solutions that make best possible use of our trees, a natural source material, while preserving our planet’s resources.

Growing trees feed on sunlight, water and the carbon dioxide from our atmosphere. The cellulose used to produce Lenzing’s fibers is a natural component in wood. At the end of our fibers’ life cycle, cellulose disintegrates into its native substances and prepares the ground for new plants to grow. Our production process mirrors this circular concept of nature: The water and chemicals we need for our production process are used over and over. They are re-circulated in our system.

The result of this circular model is perfectly sustainable: All along their life cycle, products made with Lenzing fibers promote resource preservation and environmental protection.

Lenzing works with stakeholders, certifiers and NGOs throughout the supply chain. We also use the United Nations Sustainable Development Goals as a foundation for our business focusing on SDG 7 Affordable and clean energy, SDG 9 Industry, innovation, and infrastructure, SDG 12 Responsible consumption and production, SDG 13 Climate action, SDG 15 Life on land, SDG17 Partnering for the goals.

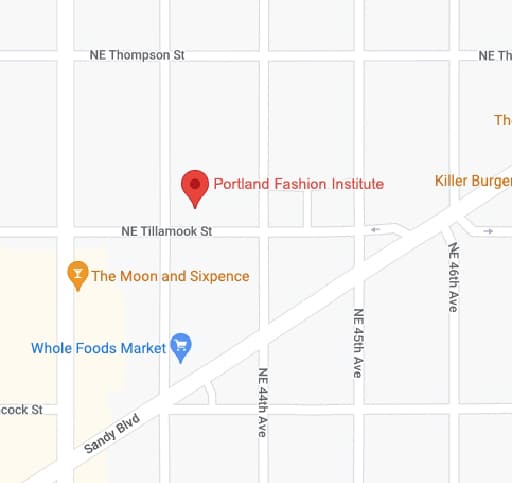

The idea of sustainability has grown and changed since the environmental movement in the 1960s. For one, it is now in the psyche of industry and design makers. To see and talk with those who are driving sustainability in the fashion industry, make plans to attend PFI’s Sustainability Tech series of seminars in Spring 2020 with Annin Barrett.

# # #