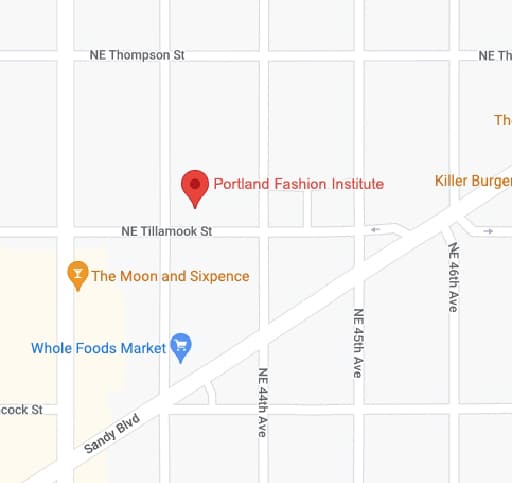

Portland Fashion Institute is a nationally accredited private nonprofit career institute of higher learning and Portland’s only accredited fashion design college.

1 block north of NE 43rd & Sandy

BUS: #12 bus

MAX: 7 blocks from the Hollywood MAX station